What type is your Aluminum and From What is It Derived

Llyod Alter formerly of Treehugger was the one I would always read on Treehugger. I would say this goes back a couple of decades. I was writing my stuff in the comments section of Slate’s Moneybox or The Best of the Fray. Somehow Treehugger became associated with Slate and I picked up on them and Lloyd.

In a most unceremonious way Lloyd was riffed out of Treehugger after many years. For all of his years at Treehugger Lloyd was let go in a rather crude, unceremonious and what I would call an unprofessional manner.

I have featured some of his articles at Angry Bear or added them to In-Box. He has a substack now and this is one of “his” commentaries. A good one on the manufacture of Aluminum.

What colour is your aluminum? It makes a massive difference, substack.com, Llyod Alter

Bloomberg recently published an inflammatory article; Ford’s Electric Pickup is Built from Metal That’s Damaging the Amazon. Authors Sheridan Prasso and Jessica Bryce claim that the aluminum Ford uses is originally sourced from an alumina refinery, Hydro Alunorte, owned by Norsk Hydro ASA of Norway, which is sickening thousands of people. The authors write:

“For consumers seeking to lower their carbon footprints, the environmental and social costs of electric vehicles may be greater than they realize. The human toll from the extraction of minerals used in batteries has been well-documented: cobalt and copper from the Democratic Republic of Congo; lithium from Chile; nickel from Indonesia. But the damage along the aluminum supply chain has been largely unexamined. It was only after Hydro and other companies announced last year that they were supplying aluminum parts for the F-150 EV that the trail back to Brazil became traceable.”

I might ask what are Phil McKenna of Inside Climate News and me at Treehugger were when we were examining this issue closely, chopped liver? But we’re not Bloomberg.

I have many problems with the F-150, both the gas and electric versions, but I think the authors were unfair to Ford in this article. The problem is universal; all virgin aluminum is made from alumina, or aluminum oxide, which is extracted from bauxite, which is mined in Jamaica, Guinea, Russia, Malaysia and Australia as well as Brazil. It’s environmentally destructive almost everywhere; As author Carl Zimring notes, “As designers create attractive goods from aluminum, bauxite mines across the planet intensify their extraction of ore at lasting cost to the people, plants, animals, air, land and water of the local areas.”

The Bloomberg article says Ford gets its aluminum from Constellium in France and from Alcoa and Rio Tinto’s smelters in Quebec, which are hydro-powered, but that “About 90% of the alumina Canada imported in 2021 came from Brazil, according to Canadian government statistics.” Then they write, confirming my point:

“That’s how Amazon-origin alumina ends up in the metal used by US auto-parts makers, as well as in beer cans, airplanes and construction materials. Along the way, it’s mixed with alumina from other refineries, including Alumar, making it difficult to say how much Brazilian bauxite or alumina from Alunorte is in any particular part.”

It’s not just Ford, it’s all aluminum. Instead of Ford, let’s take Apple. There were all kinds of headlines like Reuters, “Apple buys first-ever carbon-free aluminum from Alcoa-Rio Tinto venture,” but where do Alcoa and Rio Tinto get their alumina? Brazil. So by Bloomberg’s standard, saintly carbon-free Apple would be no different than Ford.

Nobody tells us what their supply chain really is, down to the last detail. It is what they call a “boundary” in a Life Cycle Assessment- where do you stop? How far down the rabbit hole can you go? It made it really hard to write my new book, “The Story of Upfront Carbon,” where I wrote:

“Without transparency and openness, we will never have accurate information, and with the automotive industry, we will never have transparency. They want to sell big, high-end vehicles, and they have massive upfront carbon emissions, no matter what they run on, and they are directly proportional to the size and weight.”

This is not to give Ford a pass; they use too much to make trucks that are too big. I wrote earlier that “We have to leave the bauxite in the ground and close the loop with recycled aluminum. We must use less of the stuff and stop greenwashing it.” And we need transparency.

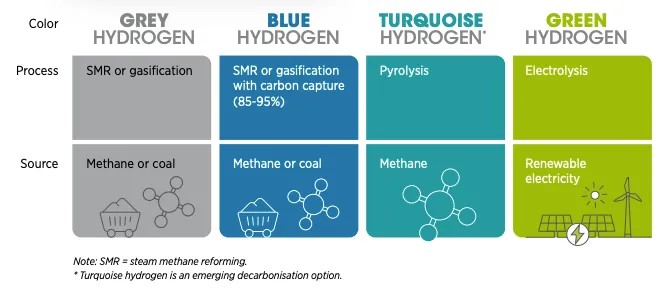

One form of transparency that we need is to know where the aluminum comes from and what its carbon footprint is. The hydrogen hypesters have adopted a form of colour scheme, with green H2 made with clean electricity, blue H2 made conventionally through the steam reformation of natural gas but with carbon capture and storage, grey H2 stripped from natural gas, and brown made from coal. There is a range of other questionable colours being added for other sources and a few different versions. It’s not a great system, and many believe that anything other than green hydrogen is just greenwashing.

But it’s better than nothing, and I proposed a colour labelling system for aluminum earlier on Treehugger, which I am expanding and refining herein.

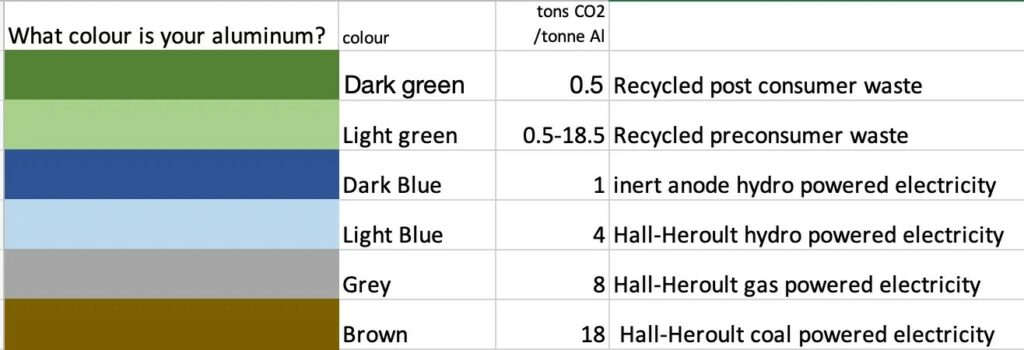

What colour is your aluminum?

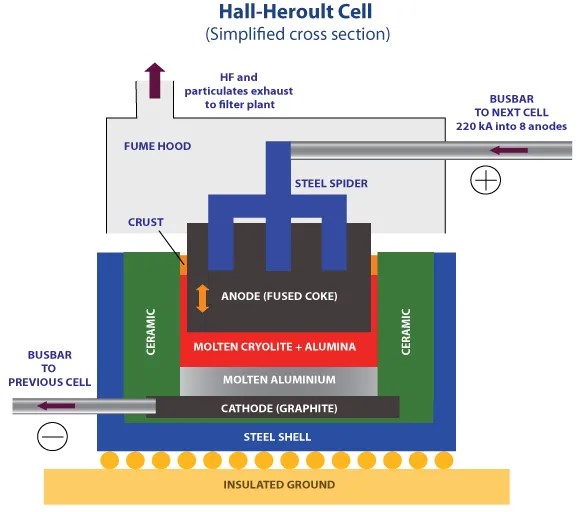

Most aluminum is made with the Hall-Héroult process, which uses vast amounts of electricity to break the bond between aluminum and oxygen, about 15 kilowatt-hours per kilogram of aluminum. In most cases, the colour of the aluminum is based on the source of the electricity.

Almost all aluminum is made this way: you dissolve alumina in cryolite or synthetic sodium aluminum fluoride and run a huge electric charge through it. The oxygen in the alumina combines with carbon from the anode to make about four tonnes of CO2 per tonne of aluminum. The aluminum sinks to the bottom and is siphoned out. If you are not careful, you get big burps of perfluorocarbons or PFCs from the cryolite breaking down, which are 7,380 times worse for climate change than carbon dioxide on a pound-for-pound basis. (more on this from Phil McKenna at Inside Climate News)

Brown Aluminum

Brown aluminum is made with coal-fired electricity, as is done in China, Australia, and the U.S., with a carbon footprint of about 18 tonnes of CO2 per tonne of aluminum. The Chinese Brown Aluminum industry is huge; Because of cheap coal, China broke production records in 2019 and, prior to the pandemic crisis, had 56% of the market. According to Christopher Clemence of Aluminium Insider, the aluminum smelters have captive coal-fired generating plants that are “granted a legal protection from the country’s environmental regulation regime.”

Grey Aluminum

In Saudi Arabia, the aluminum smelters run on electricity from natural gas, part of the kingdom’s “Vision 2030, which is a plan to diversify its economy and make it less reliant on the ever more volatile global petroleum trade.” It has a carbon footprint of about 8 tonnes of CO2 per tonne of aluminum. 362,000 tonnes of can sheet was imported from Saudi Arabia last year because there was not enough recycled aluminum on the market for the can makers. As we noted earlier,

“So everyone who feels OK drinking their beer and pop out of aluminum cans because ‘hey, they’re recycled’ should realize that they are not; there is more money in cars, so nobody is bothering, and they are just going to waste. Meanwhile, the can sheet is coming from … Saudi Arabia?”

Light Blue Aluminum

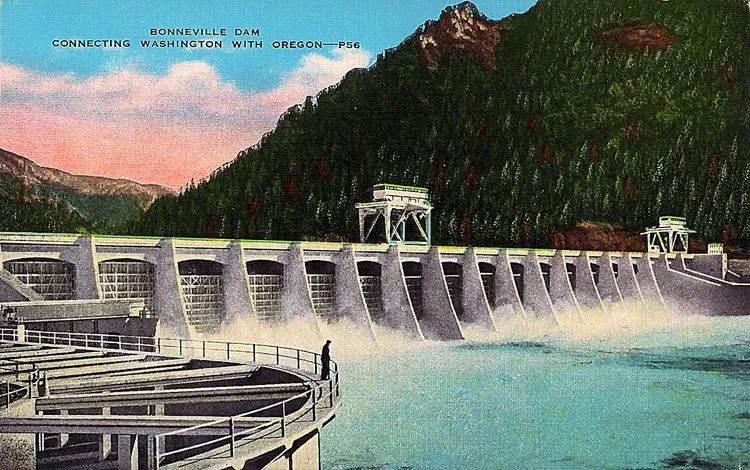

The industry likes to call aluminum made with hydroelectricity green, but blue might be a better colour since that’s the colour of water, and it is not carbon-free. Dams were built in Washington State and by the Tennessee Valley Authority before the Second World War to supply aluminum for airplanes, but now its mostly moved offshore to Russia, Norway, Iceland, and Canada.

Even hydro-powered aluminum has a carbon footprint of about 4 tonnes of CO2 per tonne of aluminum because the smelters use the Hall-Héroult process. It’s in the chemistry as well as in the electricity. This is the aluminum that, according to Bloomberg, goes into the F-150.

Dark Blue Aluminum

Some will likely disagree with me in not calling this the greenest aluminum. This is the wonderful new aluminum process that Apple has promoted and is now being done in other countries. It is “a ceramic anode for aluminum production that emits only oxygen and no greenhouse gases and last 30 times longer than those made from conventional materials.” according to the Apple press release, “This is the first time aluminum has been produced at this commercial purity, without any greenhouse gas emission and at industrial scale,” said ELYSIS CEO Vincent Christ.

But it’s not really carbon-free; according to the Financial Review, It takes about 2.5 megawatt-hours of electricity to make one tonne of alumina, and a lot of the world’s best refineries draw that power from gas generators.” At 185 kg of CO2 per mWh of gas-fired electricity, that’s 462 kg of CO2 per tonne of alumina. According to natural resources Canada, It takes approximately 4 to 5 tonnes of bauxite ore to produce 2 tonnes of alumina. In turn, it takes approximately 2 tonnes of alumina to produce 1 tonne of aluminum. At 462 kg to make a tonne of alumina, that’s a bit less than a tonne of CO2 per tonne of ELYSIS aluminum. A significant improvement, but still a significant number; you can’t call it carbon-free.

As I noted in Treehugger, the Ukraine war is affecting the world’s supply of dark blue aluminum.

Light Green Aluminum: Recycled From Pre-Consumer Waste

A few years ago, The crowd went wild when Laura Legros announced that the new Macbook Air would be made of 100% recycled aluminum. But what they are doing is collecting all the swarf from machining out the cases with a CNC machine; it is “process scrap.” As we have noted many times, “having lots of pre-consumer waste means that you are probably doing something wrong” in your manufacturing processes; it is not a badge of honor. As Matt Hickman noted in Treehugger,

“Some would say that pre-consumer recycled content isn’t even truly recycled at all because the waste involved isn’t even truly waste, if you get my drift.”

Ford is doing the same thing, picking up about 25% of the aluminum that is left after hoods, tailgates, doors and fenders are stamped into shape. “The closed-loop recycling system has helped Ford recycle more than 20 million pounds of aluminum a month, which is enough to build more than 37,000 F-series truck bodies monthly.” This is “process scrap,” and nobody wastes it; as Matt notes, this is not recycling. It’s greenwashing.

Some say it is even worse. Norsk Hydro points out that melting and processing the process scrap emits about 0.5 tonnes of CO2.

“However, the process scrap has never fulfilled its purpose as a product and thus carries the carbon footprint of the original primary aluminum from which it is produced. This means that the carbon footprint of recycled process scrap is not 0.5 tons CO2 per ton of aluminum but the carbon footprint of the original primary aluminum PLUS 0.5 tons CO2 per ton of aluminum. Some companies claim that the carbon footprint of process scrap is equal to the carbon footprint of post-consumer scrap. Such an approach would then equalize hydropower-based aluminum and coal-based aluminum as soon as the metal is processed. This approach would lead to “greenwashing”, and would favour industrial inefficiencies.”

This will be controversial, but I believe they have a point, so my colour chart has 0.5-18.5 tonnes.

Dark Green Aluminum: Recycled from Post-Consumer Waste

Finally, we have the only truly green aluminum, which is recycled from post-consumer waste. This is where we truly have to go, to a closed-loop where we stop the hugely destructive mining of bauxite and processing it into alumina. The recycling rate of aluminum is high at 67% but the rate for packaging is far lower at 37%. Much of that goes into foil pouches and multilayer materials that can’t be recycled affordably. That’s why we have to design for deconstruction and disassembly so that materials can be recovered easily and avoid what Bill McDonough called “monstrous hybrids” that can’t be taken apart. And it still has a footprint of half a tonne of CO2 per tonne of metal, which is why refilling and reusing is always better than recycling.

Last word goes to Carl A. Zimrig, who first got me really excited about aluminum with his book “Aluminum Upcycled: Sustainable Design in Historical Perspective,” he describes how we have to do a lot more than just recycling; we have to look at what we truly need. We have to use less of the stuff. It’s what I have described as sufficiency.

“The most sustainable automobile design of the twenty-first century is not the F150 aluminum pickup, or the electric Tesla, the most sustainable automotive design is not an automobile at all, but a system to distribute transportation services – car sharing, bicycle sharing, product service systems, simply owning less stuff and sharing more so that overall demand for new stuff declines. Because even such intense and virtuous recycling that we do with aluminum, even if we catch every single can and aluminum foil container, it’s not enough. We still have to use less of the stuff if we are going to stop the environmental destruction and pollution that making virgin aluminum causes.”

This is why we need transparency and these colours of aluminum. How the aluminum is made makes a massive difference in the product’s carbon footprint. We need to know what we are buying, we have to buy less of it, and we have to close the loop.

First read this paragraph:

https://news.cgtn.com/news/2023-04-23/First-megawatt-level-high-temp-superconducting-induction-heater-debuts-1jf6QiQuq6k/index.html

April 23, 2023

It used to take at least nine hours to heat an aluminum ingot weighing more than 500 kilograms from 20 degrees Celsius to 403 degrees Celsius, but the process only needs 10 minutes with the device now….

https://news.cgtn.com/news/2023-04-23/First-megawatt-level-high-temp-superconducting-induction-heater-debuts-1jf6QiQuq6k/index.html

April 23, 2023

World’s first megawatt-level high-temperature superconducting induction heating device debuts in China

The world’s first megawatt-level high-temperature superconducting induction heating device, developed by China, has been put into use in the northeastern province of Heilongjiang, China Media Group reported on Sunday.

Compared with the resistance furnace commonly used in the past, this device can double the energy efficiency conversion rate of induction heating devices, save energy by 50 percent, and reduce carbon emissions by more than half.

This device takes a new technical route, using the movement of metal in a magnetic field to generate eddy currents to heat, said Zhao Zhongxian, academician of the Chinese Academy of Science.

“I think this is a very good starting point for combining high-tech and traditional industries, which is a very important way for traditional industries’ development in the future,” he said.

It used to take at least nine hours to heat an aluminum ingot weighing more than 500 kilograms from 20 degrees Celsius to 403 degrees Celsius, but the process only needs 10 minutes with the device now….

https://investingnews.com/daily/resource-investing/industrial-metals-investing/aluminum-investing/aluminum-producing-countries/

March, 2023

1. China

Mine production: 40 million MT

2. India

Mine production 4 million MT

3. Russia

Mine production: 3.7 million MT

4. Canada

Mine production: 3 million MT

5. United Arab Emirates

Mine production: 2.7 million MT

After China developed stricter regulation, the social and environmental impacts of bauxite mining were ‘offshored’ to West Africa and Southeast Asia

The post was not about who manufactures the most. It is about the types of manufacture of Aluminum and how it impacts the environment.

The US has levied a tariff against Chinese aluminum since early 2018.

The post was not about who manufactures the most. It is about the types of manufacture of Aluminum and how it impacts the environment.

[ Surely so, and China is now generating more than 50% of electricity from non-fossil sources:

https://news.cgtn.com/news/2023-04-28/Non-fossil-fuels-exceed-50-of-China-s-energy-capacity-for-first-time-1jn0BNpGNZm/index.html

April 28, 2023

China’s non-fossil energy power generation installed capacity exceeds 50% for first time

ltr:

Changing the topic is a non sequitur.

https://news.cgtn.com/news/2023-04-26/China-takes-world-s-crown-in-nuclear-power-units-under-construction-1jjpfxcVtLi/index.html

April 26, 2023

China takes world’s crown in nuclear power units under construction

China continues to lead the world in the number of nuclear power units under construction, according to a blue book issued by the China Nuclear Energy Association (CNEA) on Wednesday.

The country has 24 nuclear power units under construction with a total installed capacity of 26.81 million kilowatts (kWs), said the blue book….

China is already 5 years ahead of meeting its UN clean energy generation commitments for 2030. The UN commitments will be met by 2025.

Changing the topic is a non sequitur.

[ Aluminum can be produced with increasing ecological soundness, and that is just what the Chinese are about and China is the prime producer. ]

ltr

That does not change your prior comment.