Farming With a Tesla

Texas is big. To frame how big, let me contextualize the normal travels for a rural resident in a few touch points that are universal. The closest large city with a decently large grocery store and a Home Depot are 37 miles one way. When running an “errand” it is easy to tack on 100 miles to the odometer in just a few hours. The parents are 42 miles away in the next city “down the highway” as it were. Sister in law 92 miles, brother 121 miles, Tesla service 96 miles, just to get out of the state 200+ miles, you get the picture. Long distances and only possibly with a personal vehicle.

The inefficiency that these vast expanses between cities present the residents are equally problematic. Run has been documenting recently, even this morning about some of the huge problems we have in consumeristic behavior regarding our transportation and vehicle choice. I offer this up as proof of concept that alternatives are not only affordable, but equally usable. Before Tesla Operations (BTO) it was easy for us to burn through 5 gallons of gas in the truck just to go get one plumbing part for a leaky faucet, setting us back $10 when gas was $1.989 a gallon. With seeking alternatives pragmatically, the costs of direct aquisition of said plumbing has diminished greatly, as have the environmental costs. No one should be taking the F-350 to the mall to shop for shoes. The cost benefit is largely not in that person’s favor and has been coached by artificially low fuel prices, leaving supply side or most recently demand side shocks to put most reeling back to some sort of affordable equilibrium.

The match was lit in 2020, the truck now six years old, 15k miles a year at a minimum, was well over the magic 100,000 mile marker that some manufacturers plan for obsolescence. Names shall not be named. A simple set of constraints and a quick analysis one Friday night and the next morning we ordered the Tesla, albeit with a long wait and a less than easy purchase, title, financing path. The main caveat, towing capabilities.

Now, the playing field had been leveled. If I needed to haul my 2,600 pound tractor and a few implements, I was well under the 3,500 threshold for the Model Y. Any need to hauling over that, employing the truck driver neighbor would always be cheaper regardless of my choice.

The math that Friday evening was rather simple, the Tesla and the comparable utility truck, the Ford F-150 were nearly comparable in price for 2020. Financed, TTL, all the same for the needed V8 power, four doors and four wheel drive. Insurance slightly higher for the Tesla due to battery pack total risk, but the main drivers were fuel costs and maintenance. The maintenance piece was a little more obscure but without regular oil changes, and other fluids, should come out ahead.

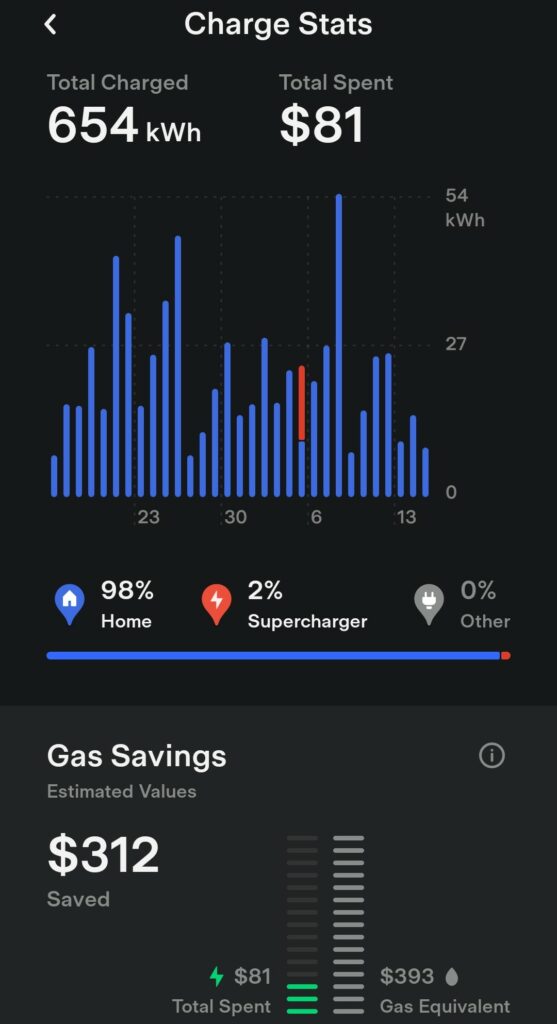

The true calculus was in the fuel savings. The Ford would get around 25 miles per gallon, when averaging between city and highway. In Texas we have a fair mix of both, but in cities there is a fair amount of start/stopping which is aggrivating. A comparable chart between the Tesla and the Ford had to be levelled first. Tesla recommends only charging up to 80% of battery capacity, which turns out to be roughly 250 miles, which was a slam dunk for head math. If the Ford is going to get 25 miles on a gallon of gas, then the gas to charge require to get to the same equivalent distance is ten gallons. At the time, unleaded would trade for $1.98 a gallon, fetching a 250 mile price of $19.89, not too shabby…but what about the Tesla? Four whole dollars, $4. When asking the Tesla maintenance tech when picking up the vehicle what unseen maintenance items am I looking at? Expensive brake pads, tires? His response, “this is your first one, huh”. Yes, and to the uninitiated, the unforseen can be huge. He then explained that the regenerative braking kept the load off the pads and that tires were marginally more expensive due to their weight requirements. A fully loaded Tesla is over 5,000 pounds. The net difference between truck tires and Tesla tires is not really a worrysome problem at all, remember, less brake pad and rotor wear, and no oil changes or transmission fuilds. It all gets back to the miles per gallon equivalent, or MPGe. This month alone, has been huge savings, albeit natural gas generation now costs me $6 to go the 250 miles. On the other hand, rounding out the month saving over $300 a month is well worth it.

The original choice flew in the face of conventional wisdom, and when I said gas will stay sub $3 for only so long, I meant it.

Now for the work load of the Tesla for farm related tasks. One will quickly find that a truck, while useful isn’t exactly a necessity. The tractor has historically been the workhorse of any farm and ranch operation. All told, a diesel engine is 13% more efficient than a gasoline one, and I would bet farm equipment is more efficient than that. With DPF filters, recirculation, farm equipment are highly efficient and cleaner than most city vehicles. I have always said, if it costs the farmer money unnecessarily, that piece of equipment, antibiotic, chemical, or new fangled doo dad will sit in the dealers lot until they have to either fire sale it or do an inventory charge off. It costs far less to move a ton of X with a diesel tractor than the bed of a gas truck.

Fast forward to today where unleaded prices are now in my area hitting $4.59 a gallon. The Ford is now spending $45.90 for the same 250 mile trip, and the Tesla $6. The annual difference is clocking in at $3,200 in savings, and could be higher given the current price trends. I know not all can afford expensive electric vehicles and we need to explore alternative transportation that makes sense for the masses in inner cities. This is but one piece of the energy solution puzzle, one that gets bucked hard from all sides due to cost and political whims. Embracing the future shouldn’t be a political one. Pragmatism should be celebrated, in all facets, even if that means taking the bus.

Thanks for an interesting take on things. I hadn’t considered that a Tesla would make so much sense in a rural area. I definitely hadn’t considered that their high torque electric motors could handle towing as well as they do. I always thought of it as a city or suburban car. Apparently, we’re just seeing the start of the revolution.

The battery degredation is comparable to the additional gas draw on an ICE vehicle, which some misconstrue. EVs are actually really good at towing, hauling, groceries, going to grandmas, all of the above.

I have been after Elon for awhile now to bring the cyber truck out we would grab a ranch trailer and haul some cattle around as a show of force. I’m still working on it.

MS;

Yes on the torque. It is there from the beginning of acceleration. That is what makes this interesting.

The battery degradation is comparable to the additional gas draw on an ICE vehicle,…

Mike, do you have some numbers on the amount of degradation on the batteries when towing. I ask, because Ford promoting their EV truck does not seem to mention that. An EV truck is no good if the distance degrades significantly while towing it’s max capacity.

With that, a youtuber I watch was at a trade show for heavy equipment and at the Volvo booth they were showing off their EV small excavator and articulated loader.

Full on load I’ve seen people pull around 83 miles round trip on a full charge, and I assume that’s at 80% battery. I usually haul half a ton of compost and the trip usually will eat up 26% of the battery no tow, with trailer on there is a trick, but I can get it to around 40% or so battery use.

I was pitched an electric tractor. Was a hard no go. The amount of energy required to run equipment is huge, which is why the fuel is always diesel. LNG, propane, gasoline, etc. don’t hold a candle to a diesel engine.

Yes, regarding heavy equipment. It will be interesting to see how this pans out for Volvo. They noted that the machines have been in their native country for a year or more. Here is the part of the video about the electric machines: https://youtu.be/JHoqEhQ1H9w?t=772

Becker – went down a rabbit hole with that one and one thing I have to say is what is being done about heat? Volvo claims that they can get 4 hours of work out of a loader, but at 60 degrees, or 90? The difference is huge because the battery have to be kept at optimal temperature.

I assume also this is powering a hydraulic pump, like most heavy equipment. So I have to ask at what flow rate and how long. The videos I saw looked promising but to go four hours at most and then have to char for 12 will immediately put almost everyone out and the 2.4 million price tag is a definite no.

Michael Smith

yes, perhaps, but lets not thow the pig out with the bath water.

an electric town car, or a gas-electric road car, or an electric town car and a fully gas touring car would slow down the rate of CO2 emissions to put stopping climate change. or would have if we started when we first knew this was coming. looking at pictures of lake powell and lake mead it occured to me we are more likely to get Sahara than Jurassic Park.

eye on the prize, m’boys, eye on the prize.

as for town and suburb. you don’t need hundred plus mile range or 60 mph. commutes on LA freeways usd to run at about 12 m/h. so something like a golf cart ought to do the job. and you show the way by going ahead and buying that freeway cruiser, but save it for the times it makes sense.

of course that time has long passed.

when i was a kid we had a farm truck so old i couldn’t read the label. took it into town, about twenty miles one way, once a week or so. it pays to plan ahead. as for seeing the relatives a hundred miles away every weekend. i wouldn’t.

Mike,

I only presented the Volvo to let the readers know that this is happening. Sure, may not be viable for all, a rather limited market but it is happening. I would have never thought we were at this point in EV development such that a company was applying it to earth moving equipment.

Volvo has a lot more money tied up in this than I would say Ford has in their truck so…they have to be seeing something in the future.

Yes, everything is hydro on equipment these days. Though, my 2 Bolens from the early 70’s are hydro drive so nothing new. But, torque multiplying tech, varying flow and most likely some type of computer demand management system just like when dealing with the electrical requirements/demands of today’s vehicles. There has to be a way they have managed the power demands of the pump (s), thus the motor demand for current. Maybe multiple motors and pumps of smaller size vs 1 big pump flowing through all hydro circuits all the time? I would think they have calculated the max efficiency of power via hydro flow volume vs pressure vs electical draw to get the most out of the battery pack. Limit the load/unload demand on the pump thus motor as a valve is opened/closed such that it stays a more constant electric draw or maybe it’s better to simple start/stop the motor as the valve is opened/closed?

The only way I can see this being practical in a daily contracting operation is if the battery packs were simple plug in just like my cordless drill…be it bigger. Have 2 or 3 packs so there is one always ready to go. But, I did not see that as an option.

Any ways, it’s interesting.